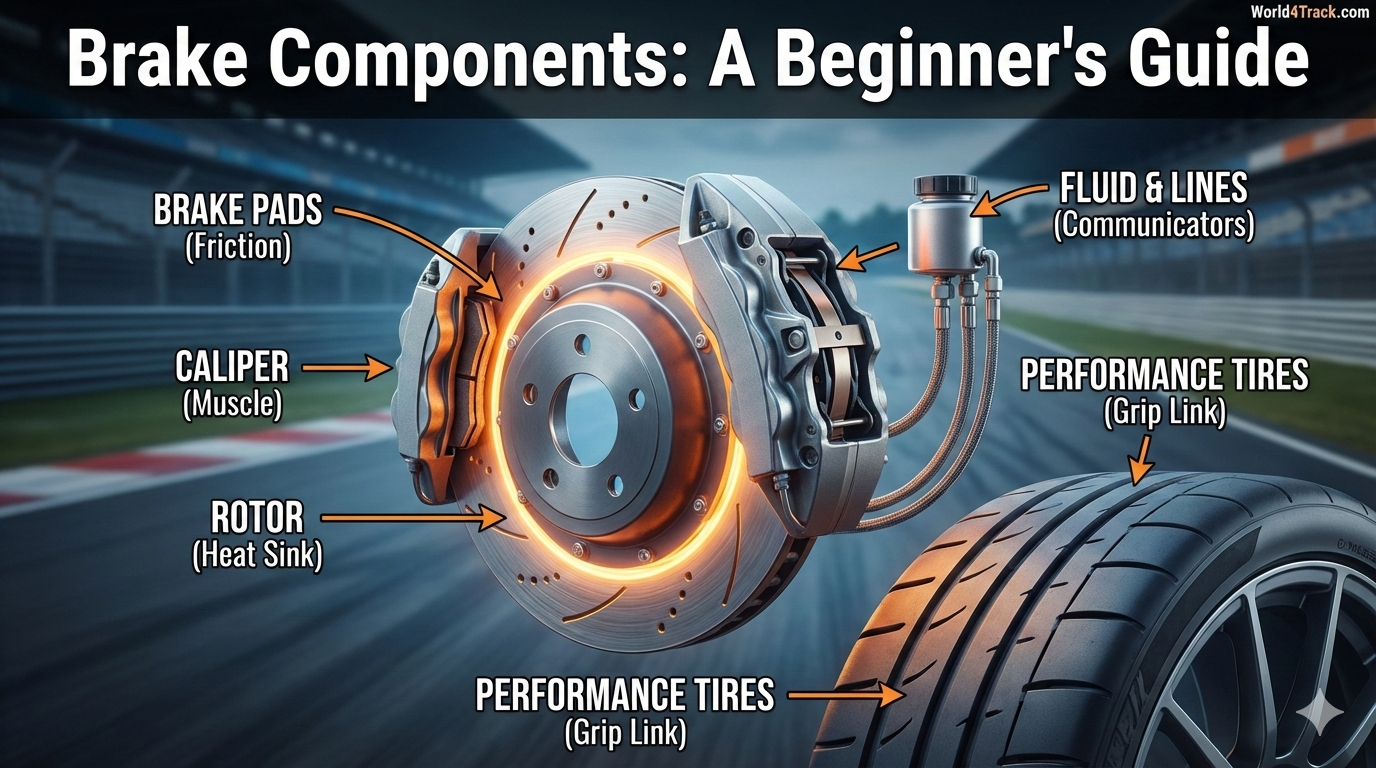

Brake Components: A Beginner's Guide to Track Performance

Stopping power is just as important if not more so than horsepower. If you are new to the world of track days and performance cars, the terminology surrounding brake systems can feel overwhelming. You might hear terms like "fading," "initial bite," or "boiling fluid" thrown around in the paddock.

In this guide, we will break down the essential brake component functions and explain how they work together to keep you safe and fast on the circuit. Consider this your roadmap to performance car basics before you start modifying.

How Does a Performance Brake System Work?

At its core, a brake system converts the kinetic energy of your moving car into heat energy through friction. When you press the brake pedal, you are activating a hydraulic system that clamps friction material onto a spinning disc, slowing the wheel down.

For a track car, the goal isn't just to stop once; it is to stop repeatedly from high speeds without losing effectiveness. This is where aftermarket upgrades become essential.

1. The Brake Pads: The Friction Specialists

The brake pad is the component that makes physical contact with the spinning rotor. It is the frontline soldier in the battle against speed.

Function: Pads clamp onto the rotor to create friction.

Track vs. Street: Street pads prioritize low dust and silence. Track pads prioritize high heat tolerance and consistent friction levels.

If you stick with stock pads on a track, you will likely experience "brake fade," where the pad gets too hot and loses its grip. Upgrading to a compound designed for higher temperatures is often the first step for any enthusiast.

Deep Dive: Want to know specifically which compound suits your driving style? Read our detailed breakdown here: The Ultimate Guide to High-Performance Pads.

2. Brake Rotors: Managing the Heat

The rotor (or disc) is the metal circle that your wheels are bolted to. While the pads create the heat, the rotors must absorb and dissipate it.

Function: Provides a surface for pads to grip and acts as a heat sink.

Performance Factor: On track, rotors act like radiators. Vented, slotted, or drilled designs help expel hot gases and cool the metal down faster to prevent warping or cracking.

Deep Dive: Confused about the difference between slotted, drilled, and blank discs? We cover everything you need to know in this article: Understanding Brake Rotors for Track Cars.

3. Brake Calipers: The Muscle

If the pads are the hands that grab the rotor, the caliper is the muscle that squeezes them together.

Function: Houses the pistons that push the pads against the rotor.

Floating vs. Fixed: Most road cars use "floating" calipers (usually 1 piston). Performance cars often use "fixed" calipers (4, 6, or even 8 pistons) for more even pressure distribution and better pedal feel.

4. Brake Fluid and Lines: The Communicators

Often the most overlooked track car essentials, fluid and lines transmit the force from your foot to the caliper.

Brake Fluid: Track driving boils standard fluid quickly, leading to a spongy pedal that goes to the floor. High-temp racing fluid is a safety necessity.

Braided Lines: Stock rubber hoses expand under pressure. Upgrading to stainless steel braided lines ensures that all your pedal effort goes into clamping the rotor, not swelling the hose.

5. The Critical Link: Performance Tires

It is a common mistake in performance car basics: spending thousands on brakes while running budget tires. Here is the golden rule: Brakes stop the wheels, but tires stop the car.

The Limiting Factor: If your new, aggressive brakes lock up the wheels (or trigger ABS) instantly because the tires lack grip, your brake upgrade is wasted.

Matching Components: To truly feel the benefit of aftermarket calipers or pads, you must match them with a tire compound that has high grip levels. Your braking system is only as strong as its weakest link—which is usually the rubber meeting the road.

FAQ: Common Questions About Brake Upgrades

What is the first brake upgrade I should do for a track car?

For most beginners, the best first upgrade is high-temperature brake fluid and performance brake pads. These offer the biggest improvement in safety and consistency without breaking the bank.

Do I need big brakes to go to the track?

No, you do not necessarily need a "Big Brake Kit" (BBK) for your first track day. A well-maintained stock system with upgraded pads and fluid is sufficient for beginners learning performance car basics.

Why do my brakes squeal after upgrading?

Performance brake pads often contain metal content to handle high heat. This creates more noise than softer street pads. On a track car, a bit of squeal is usually a sign of high-friction capability, not a malfunction.

Ready to Upgrade Your Stopping Power?

Understanding your braking system is the first step toward faster lap times. By ensuring your pads, rotors, and fluid are up to the task, you can drive with confidence, knowing the car will stop when you need it to.

If you are ready to start modifying, browse our curated selection of aftermarket upgrades directly at our store: 👉 Visit the World4Track Shop

Not sure which setup is right for your specific vehicle? We are happy to help you plan your build. 👉 Contact Us for Expert Advice